The Internet of Things (IoT) technology transforms how businesses and consumers interact with devices. It is an interconnected network of devices that enables seamless communication and data exchange between them. With the rapid advancements in IoT technology solutions, the number of IoT devices is increasing exponentially yearly, leading to a surge in IoT applications.

IoT technology trends drive digital transformation across healthcare, manufacturing, transportation, and logistics industries. IoT solutions enable businesses to monitor and manage their assets in real time, optimize their processes, and enhance customer experience.

Understanding the application enablement platform (AEP)

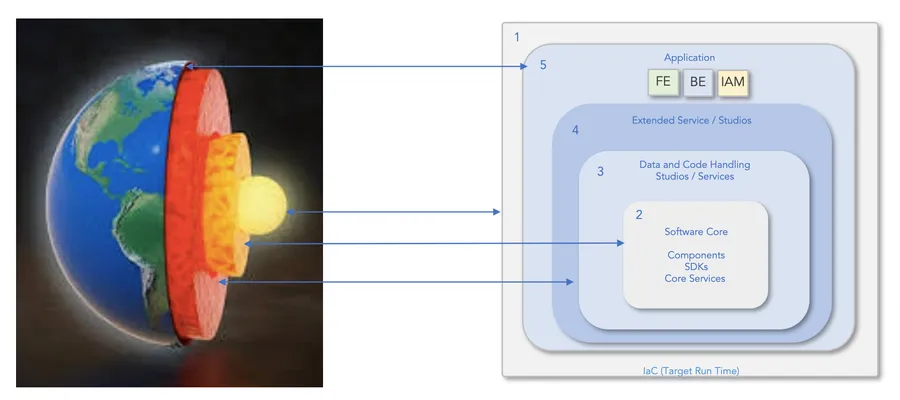

Before we dig any further into IoT technology, it’s necessary to know how an application enablement platform assists in delivering customized IoT applications. An IoT AEP is a technology solution designed to provide a flexible, adaptable middleware core that can support the creation of multiple interconnected or standalone IoT solutions across various industries. An Application Enablement Platform (AEP) is vital for building scalable IoT solutions. It provides essential components such as:

- A strong-core Microservices Architecture scaled at more than 65 Million devices.

- Low-code studios accelerate the overall application development process.

- A brand-led Device Lifecycle Management application built with minimal effort.

- Ability to build and launch multiple applications with the lowest time-to-market and couple them with tenant administration services, allowing brands to offer a customizable licensing model to the customers.

These components are necessary for overcoming any challenges associated with IoT development. As the demand for IoT applications grows, AEPs have become increasingly popular among teams looking to streamline the development process and address foundational obstacles. By leveraging the capabilities of an AEP, developers can focus on building innovative IoT applications that meet the needs of their customers.

How IoT enablement is transforming the manufacturing industry

The Internet of Things (IoT) and enablement have transformed the manufacturing industry, transforming how manufacturers approach production, maintenance, and supply chain management. IoT-enabled devices and sensors make monitoring and controlling every aspect of the manufacturing process in real-time more accessible. Below are the top 10 real-world applications of IoT technology in manufacturing:

- Predictive Maintenance

Predictive maintenance is one of the most significant benefits of IoT technology in manufacturing. With IoT-enabled sensors, manufacturers can monitor equipment performance in real time and detect any anomalies that could lead to equipment failure. This information allows manufacturers to schedule maintenance proactively, reducing downtime and preventing costly repairs.

- Quality Control

IoT technology is helping manufacturers maintain quality control by monitoring every stage of the production process. Manufacturers can identify product quality issues by collecting sensor data, such as temperature fluctuations or production line interruptions. With real-time insights, manufacturers can take corrective action to maintain quality and prevent defects.

- Inventory Management

IoT technology is streamlining inventory management processes for manufacturers. With sensors placed on inventory, manufacturers can track inventory levels in real time and receive alerts when stock levels are low. It allows manufacturers to order materials or products before stock runs out, reducing the risk of production delays and lost sales.

- Supply Chain Management

IoT technology transforms supply chain management, making tracking products from production to delivery easier. With IoT-enabled sensors, manufacturers can track shipments, monitor delivery times, and predict potential delays. This information allows manufacturers to optimize their supply chain and ensure on-time delivery, improving customer satisfaction and reducing costs.

- Worker Safety

IoT technology is also improving worker safety in manufacturing. With sensors placed on equipment, manufacturers can monitor worker activity and detect unsafe behaviors. This information allows manufacturers to provide real-time feedback to workers and improve safety protocols, reducing the risk of accidents and injuries.

- Energy Efficiency

IoT technology is helping manufacturers improve energy efficiency and reduce energy costs. With sensors placed on equipment and machinery, manufacturers can monitor energy consumption in real-time and identify areas for improvement. This information allows manufacturers to optimize energy usage, reduce waste, and save money on energy bills.

- Production Optimization

IoT technology is helping manufacturers optimize their production processes with industry 4.0 solutions. With sensors placed on machines and equipment, manufacturers can monitor production data, including machine utilization, downtime, and product quality. This information allows manufacturers to identify inefficiencies and bottlenecks, optimize production processes, and increase productivity.

- Remote Monitoring

IoT technology enables remote monitoring of manufacturing operations. It also enables remote troubleshooting and maintenance, lowering the need for on-site visits and reducing downtime. With IoT-enabled sensors and devices, manufacturers can monitor production data from anywhere, anytime, improving flexibility and efficiency.

- Asset Tracking

IoT technology is helping manufacturers track and manage their assets. With smart-edge applications and sensors placed on equipment and machinery, manufacturers can monitor asset location, utilization, and maintenance requirements. This information allows manufacturers to optimize asset usage, reduce downtime, and save money on maintenance costs.

- Smart Factories

IoT technology is enabling the development of smart factories. Manufacturers can create a fully automated and interconnected manufacturing environment with IoT-enabled devices and sensors, improving efficiency and reducing costs. Smart factories can leverage real-time data to optimize production, reduce waste, and increase productivity.

Conclusion

IoT technology is revolutionizing the manufacturing industry, providing unprecedented efficiency, cost savings, and safety improvements. With IoT-enabled devices and sensors, manufacturers can monitor and control every aspect of their operations in real-time, resulting in greater accuracy, reduced waste, and increased productivity.

Research indicates that the IoT application enablement market is expected to rise from 2.7 Bn USD in 2021 to 36 Bn USD by 2032, with demand growing at a CAGR of 26.5% over the forecast duration.

At IoT83, we understand the unusual challenges facing the manufacturing industry, and we offer customized IoT solutions through our AEP product, Flex83. Unlike other service providers who supply standardized IoT solutions with a one-size-fits-all approach, we tailor our solutions to meet the specific needs of your business, ensuring maximum ROI and long-term success.

Feel free to reach us if you want to discover more about how IoT83 can help transform your manufacturing operations with innovative IoT technology. Our team of experts is standing by to provide personalized consultation and guide you through building a custom IoT solution that fits your unique requirements.