Overcoming the challenges of siloed infrastructure in Industrial Internet of Things (IIoT) environments involves strategic, technological, and organizational efforts. It aims at data sharing, collaboration, enhancing connectivity, and interoperability across different systems and departments. However, the presence of data silos can restrict progress, leading to a lack of communication and decreased productivity.

What is Siloed Infrastructure in Industrial IoT?

A siloed infrastructure refers to a scenario where different IIoT devices, systems, and data sources within an industrial environment operate independently, with limited or no interoperability or communication between them. It occurs due to various factors, including the use of proprietary technologies, lack of integration standards, or organizational barriers. Siloed infrastructures in IIoT environments can lead to several challenges and inefficiencies, impacting the overall performance and effectiveness of industrial operations.

Impacts of Siloed Infrastructure on an Organization

In general, siloed infrastructures are more commonly associated with negative impacts on business operations and goals. However, there can also be situational benefits. Both are listed below.

Positive Impact of Siloed Infrastructure

In some cases, siloed infrastructure within Industrial IoT can offer unexpected benefits. Specialization within departments fosters deep expertise in specific areas, leading to high-quality work in those domains. Siloed data and processes can also improve security and compliance by restricting access in sensitive areas. Additionally, managing and making decisions within silos can be more straightforward, as the broader organizational impact doesn’t need to be considered for every action.

Negative Impact of Siloed Infrastructure

Siloed infrastructure in Industrial IoT can significantly hinder an organization’s efficiency and innovation. Poor communication and redundant efforts across units lead to operational inefficiencies. Limited information sharing and collaboration stifle early actions and the capabilities to adapt quickly to changes. Siloed data also makes it difficult to get a holistic view of the specific process, resulting in slower decision-making and missed opportunities. Furthermore, maintaining multiple isolated systems increases IT complexity and overall costs.

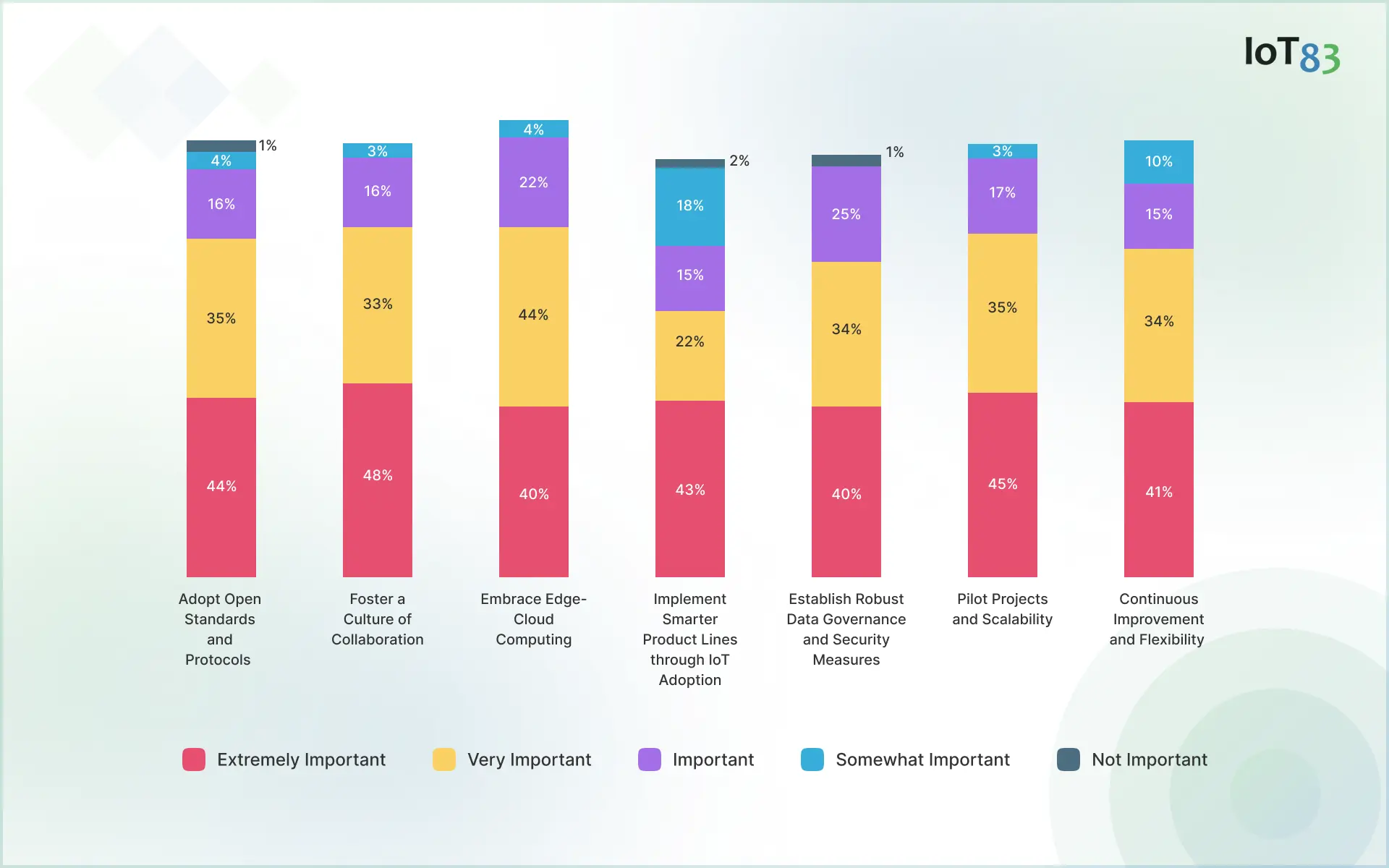

7 Best Practices to Overcome the Siloed Infrastructure in IIoT

1. Adopt Open Standards and Protocols

- Use standardized communication protocols such as MQTT, AMQP, or OPC UA to facilitate easier integration and data exchange between devices and systems.

- Leverage industry standards for data modeling and interoperability, such as those from the Industrial Internet Consortium (IIC) or the International Society of Automation (ISA), to ensure compatibility and ease integration efforts.

2. Foster a Culture of Collaboration

- Encourage cross-departmental collaboration to break down silos within the organization. This can involve creating interdisciplinary teams focused on IoT projects that span different operational areas.

- Promote knowledge sharing through regular meetings, workshops, and training sessions. It can help ensure all stakeholders understand the benefits of integrated IIoT systems and how to leverage them effectively.

3. Embrace Edge Cloud Computing

- To realize the value of Business Transformation, OEMs have to integrate this new IoT data into smart applications and smart solutions or this IoT Edge data.

- Edge Computing processes data closer to where it is generated, reducing latency and bandwidth use and enabling real-time decision-making. This can help integrate processes across different locations and systems by providing a standardized approach to data processing and analytics.

4. Implement Smarter Product Lines through an IoT Platform

- Deploy an IoT platform that can act as a middleware layer to connect disparate systems, allowing for data aggregation, visualization, and analysis in a centralized location.

- Choose platforms that support multi-protocol integration and can interface with both legacy systems and newer IoT devices to bridge the gap between old and new technologies.

5. Establish Robust Data Governance and Security Measures

- Address data ownership, access controls, and quality standards with a comprehensive data governance framework. Ensure data is shared and used effectively across the organization.

- Prioritize cybersecurity by adopting best practices for securing IoT devices and networks, including regular updates, encryption, and intrusion detection systems, to protect against threats that could exploit interconnected systems.

6. Pilot Projects and Scalability

- Demonstrate the value of integrated systems with pilot projects and gather insights before scaling up. This allows for identifying potential issues and proving the concept in a controlled environment.

- Plan for scalability by choosing solutions and architectures that can grow with your IoT deployment, ensuring the system can handle increasing data volumes and more complex integrations as your IIoT ecosystem expands.

7. Continuous Improvement and Flexibility

- Adopt a mindset of continuous improvement, where feedback from IoT systems is used to refine processes and integration strategies over time.

- Stay flexible and open to adopting new technologies and practices as the IIoT landscape evolves, ensuring your infrastructure can adapt to future needs and opportunities.

By addressing these areas, organizations can overcome the challenges of siloed IIoT infrastructures, paving the way for more efficient operations, better decision-making, and enhanced innovation. The need of the hour for OEMs is to upgrade traditional unconnected products with connected data and then add this IoT data to new OEM services like Asset Performance Monitoring, Asset Remote Management, Predictive Maintenance, Optimized FieldOps, and even new business models like Equipment as a Service.

Flex83 is a rapid application development system that lets teams focus directly on creating this new differentiation without the overhead delays and risks of the underlying technology. It can be the best solution to enhance interoperability, such as adopting industry standards, implementing integration platforms, and fostering collaboration across different departments and teams. Here are various ways Flex83 can help you get out of a siloed infrastructure.

- Support cross-functional communication

- Consolidating data into a single repository, Centralize data

- Retire legacy systems

- Establish a data governance framework

- Defined and transparent processes

All of this works to unblock your path to a powerful competitive advantage for your business now and in the future. Let’s connect to discuss a siloed infrastructure solution further, specifically for your business needs.

Nishant Puri, Co-Founder & CISO at IoT83

Nishant carries professional expertise in team collaboration and network security solutions. He excels at aligning the needs of key business stakeholders, including Sales, Marketing, and Product Engineering, with pragmatic and efficient approaches that meet both short-term and long-term strategic goals.

Before joining IoT83, Nishant held a leadership position at Cisco America Partners, where he led sales and technology solutions. He was also a frequent speaker for Cisco APO, showcasing his knowledge and experience in the field. Being a Cisco-certified Inter-Networking Expert in Security and Collaboration, Nishant brings a wealth of technical expertise to his role. He is also inclined to identify digital discontinuities and is adept at mapping out effective digital transformations.